Wind Energy Inspection

Drone Wind Farm Survey Services

Comprehensive wind turbine inspection using advanced drone technology. Faster, safer, and more cost-effective than traditional rope access methods.

Response within 2 hours - Or call 020 4634 0456

What Is a Drone Wind Farm Survey?

A drone wind farm survey uses specialist UAV technology to inspect wind turbine blades, towers, and nacelles without the need for costly rope access teams or turbine shutdowns. Our high-resolution cameras capture detailed imagery of every blade surface, identifying defects, erosion, and damage that could impact performance or safety.

At Drone Survey Services, we deploy advanced drone platforms equipped with high-resolution zoom cameras and thermal sensors. Our pilots are trained specifically for wind turbine inspection, understanding the unique challenges of capturing consistent imagery across all blade surfaces while managing wind conditions and turbine geometry.

James Leslie

Owner, Engineer & Drone Pilot

"Got questions? Call me directly - I'm happy to talk through your project."

Call NowProfessional Wind Turbine Inspection,Without the Risk

What You'll Receive

- High-resolution blade imagery

- Defect identification report

- Condition assessment grading

- Maintenance recommendations

Delivered in 3-5 working days

Why Choose Us

- CAA approved & fully insured

- Wind turbine inspection specialists

- No turbine shutdown required

- UK-wide coverage

Trusted by wind farm operators and asset managers across the UK.

Trusted by leading organisations

How Much Does a Drone Wind Farm Survey Cost?

Pricing depends on the number of turbines and scope of inspection. Here's a guide to help you budget:

| Project Size | Guide Price |

|---|---|

| Single Turbine1 turbine | £400+ |

| Small Farm1-5 turbines | £1,200+ |

| Medium Farm5-15 turbines | £2,500+ |

| Large Farm15+ turbines | POA |

| Recurring InspectionAnnual contract | POA |

*Guide prices include standard deliverables. Final quote based on turbine model, blade length, access, and specific requirements.

What affects your quote?

- Number of turbines

- Blade length & model

- Site location & access

- Weather windows

Our drone-based approach typically saves 60-80% compared to traditional rope access inspection. Contact us with your project details and we'll provide a tailored quote within 24 hours.

Ready to get a quote for your wind farm?

Free, no-obligation quotes within 24 hours

What Is the Difference Between Drone Wind Farm Survey and Rope Access?

Traditional rope access inspection requires trained technicians to abseil down turbine blades—a time-consuming, weather-dependent process that typically requires the turbine to be shut down. A single turbine inspection can take an entire day and involves significant health and safety considerations.

Drone wind farm survey captures equivalent or better imagery in a fraction of the time. Our UAVs can inspect a turbine in 20-30 minutes, often without requiring shutdown. This means less production loss, lower costs, and faster turnaround on inspection reports—critical advantages for maximising your wind farm's operational efficiency.

When to Choose Each Method

Choose Drone Survey

Fast & cost-effective

Choose Rope Access

Hands-on intervention

Not sure which approach suits your needs?

What Accuracy Can a Drone Wind Farm Survey Achieve?

Our drone wind farm surveys capture imagery at resolutions of 1-2mm per pixel on blade surfaces—sufficient to identify hairline cracks, leading edge erosion, lightning damage, and coating defects. We use high-resolution zoom cameras that can maintain safe standoff distances while still capturing the detail needed for accurate condition assessment.

Thermal sensors detect subsurface defects, delamination, and moisture ingress that aren't visible to the naked eye. Combined with our systematic inspection methodology covering all blade surfaces (pressure side, suction side, leading edge, and trailing edge), we provide comprehensive condition data that meets or exceeds industry standards for blade inspection.

What Are the Applications of Drone Wind Farm Survey?

Drone wind farm survey has become the industry standard for turbine inspection across numerous applications. Here's where our clients see the greatest value:

Routine Blade Inspection

Annual or bi-annual blade condition assessments to monitor degradation, identify emerging defects, and prioritise maintenance activities.

Post-Storm Damage Assessment

Rapid inspection following severe weather events to assess blade integrity and identify lightning strikes or impact damage.

Warranty Claims

Documented evidence of manufacturing defects or premature wear for warranty discussions with turbine manufacturers.

Pre-Purchase Due Diligence

Independent asset condition assessment for wind farm acquisitions, providing accurate data for investment decisions.

End of Warranty Inspection

Comprehensive inspection before warranty expiry to identify and document any defects covered under manufacturer warranty.

Tower & Nacelle Inspection

Visual inspection of tower sections, nacelle housing, and auxiliary components for corrosion, damage, or maintenance issues.

Have a wind farm inspection requirement?

Can Drones Inspect Wind Turbine Blades?

Yes—drone blade inspection has become the preferred method for wind farm operators worldwide. Modern drone technology combined with high-resolution cameras and thermal sensors provides comprehensive blade condition data that matches or exceeds traditional inspection methods.

Our inspection methodology captures every blade surface systematically. We photograph the leading edge, trailing edge, pressure side, and suction side of each blade, creating a complete visual record. Our pilots are trained to identify and document all common defect types:

- Leading edge erosion – Surface wear from rain, insects, and particles impacting blade efficiency

- Lightning damage – Entry/exit points and receptor condition assessment

- Cracks and fractures – Surface cracks, delamination, and structural damage

- Coating defects – Peeling, blistering, and protective layer damage

- Foreign object damage – Bird strikes, debris impact, and external damage

What Deliverables Do You Get From a Drone Wind Farm Survey?

We tailor deliverables to your requirements, but our standard wind farm inspection outputs include:

High-Resolution Blade Imagery

Complete photographic record of all blade surfaces organised by turbine, blade, and section for easy reference and comparison.

Defect Identification Report

Detailed documentation of all identified defects with location mapping, severity grading, and annotated imagery.

Condition Assessment Grading

Standardised condition scoring for each blade enabling comparison across your fleet and tracking of degradation over time.

3D Blade Models (Optional)

Photogrammetric 3D models for advanced analysis, measurement, and integration with asset management systems.

Maintenance Recommendations

Prioritised repair recommendations based on defect severity, helping you plan maintenance activities efficiently.

Thermal Analysis Report

Infrared imagery identifying subsurface defects, delamination, moisture ingress, and thermal anomalies not visible to standard cameras.

Need specific deliverables for your inspection programme?

How Long Does a Drone Wind Farm Survey Take?

On-site inspection is remarkably efficient. We can typically inspect 8-12 turbines per day depending on blade length and weather conditions. A single turbine inspection takes 20-30 minutes of flight time, plus setup and blade positioning coordination.

Report delivery depends on the number of turbines and analysis requirements. Standard inspection reports are typically ready within 3-5 working days. For urgent post-incident assessments, we offer expedited 24-48 hour turnaround. We'll confirm realistic timescales when we quote your project.

| Phase | Duration |

|---|---|

| Planning & Coordination | 1-3 days |

| On-Site Inspection | 1-3 days |

| Image Processing | 1-2 days |

| Analysis & Reporting | 2-3 days |

| Total (Standard) | 3-5 working days |

Rapid Response Available

Post-incident or urgent inspections: 24-48 hour turnaround available.

How Do I Choose a Drone Wind Farm Survey Provider?

Not all drone operators have the experience and capability for wind turbine inspection. When evaluating providers, we recommend checking these key factors:

- CAA authorisation – Ensure they hold valid GVC or legacy PfCO permissions for commercial operations

- Wind farm experience – Ask specifically about turbine inspection projects and methodologies

- Appropriate insurance – Public liability and professional indemnity for wind farm operations

- Equipment capability – High-resolution zoom cameras and thermal sensors for comprehensive inspection

- Reporting quality – Request sample reports to assess their defect identification and classification approach

At Drone Survey Services, we tick every box. We're CAA approved, fully insured, and have delivered wind farm inspection projects across onshore sites throughout the UK. Our systematic inspection methodology ensures consistent, reliable results.

Ready to work with a trusted wind farm inspection provider?

Is Drone Wind Farm Survey Cheaper Than Rope Access?

Significantly—typically saving 60-80% compared to traditional rope access inspection. The economics are compelling: rope access requires a team of qualified technicians, extensive safety equipment, and often a full day per turbine. The turbine must be shut down, resulting in lost production revenue.

Our drone approach inspects the same turbine in under 30 minutes, often without requiring shutdown. We can cover 8-12 turbines per day versus 1-2 for rope access teams. When you factor in reduced downtime, lower mobilisation costs, and faster turnaround on reports, drone inspection delivers exceptional value. For large wind farms or recurring inspection programmes, the savings become even more substantial.

Ready to Discuss Your Wind Farm Inspection?

Expert advice - Competitive pricing - Response within 2 hours

James Leslie

Owner, Engineer & Drone Pilot

With extensive experience in drone operations and wind turbine inspection, James personally oversees every wind farm project to ensure comprehensive coverage and professional delivery.

TLDR: Drone Wind Farm Survey Explained

Wind Farm Survey Deliverables

- High-resolution blade imagery

- Defect identification reports

- Condition assessment grading

- 3D blade models (optional)

- Maintenance recommendations

- Thermal analysis report

Discuss Your Project

Get expert advice and tailored pricing.

Enterprise Equipment

Survey-Grade Drone Fleet

We don't use consumer mini drones like other providers. Our fleet consists of industrial, survey-grade aircraft purpose-built for capturing detailed, accurate datasets.

AgEagle eBee X

Professional fixed-wing for rapid terrain coverage

DJI Matrice 400

Engineered for excellence, designed for versatility

WingtraOne GEN II

Best-in-class surveying efficiency for large projects

DJI Matrice 350 RTK

Professional multi-payload platform for precision surveying

DJI Mavic 4E

Portable surveying powerhouse with RTK precision

DJI Matrice 300 RTK

Industry-leading inspection and mapping platform

DJI Matrice 4E

Precision survey drone with oblique capture

1 of 7

← Swipe to explore fleet →

Sensor Technology

Specialised Sensors for All Aerial Surveys

Our aircraft carry professional-grade sensors matched to your project requirements, from high-resolution photogrammetry to terrain-penetrating LiDAR.

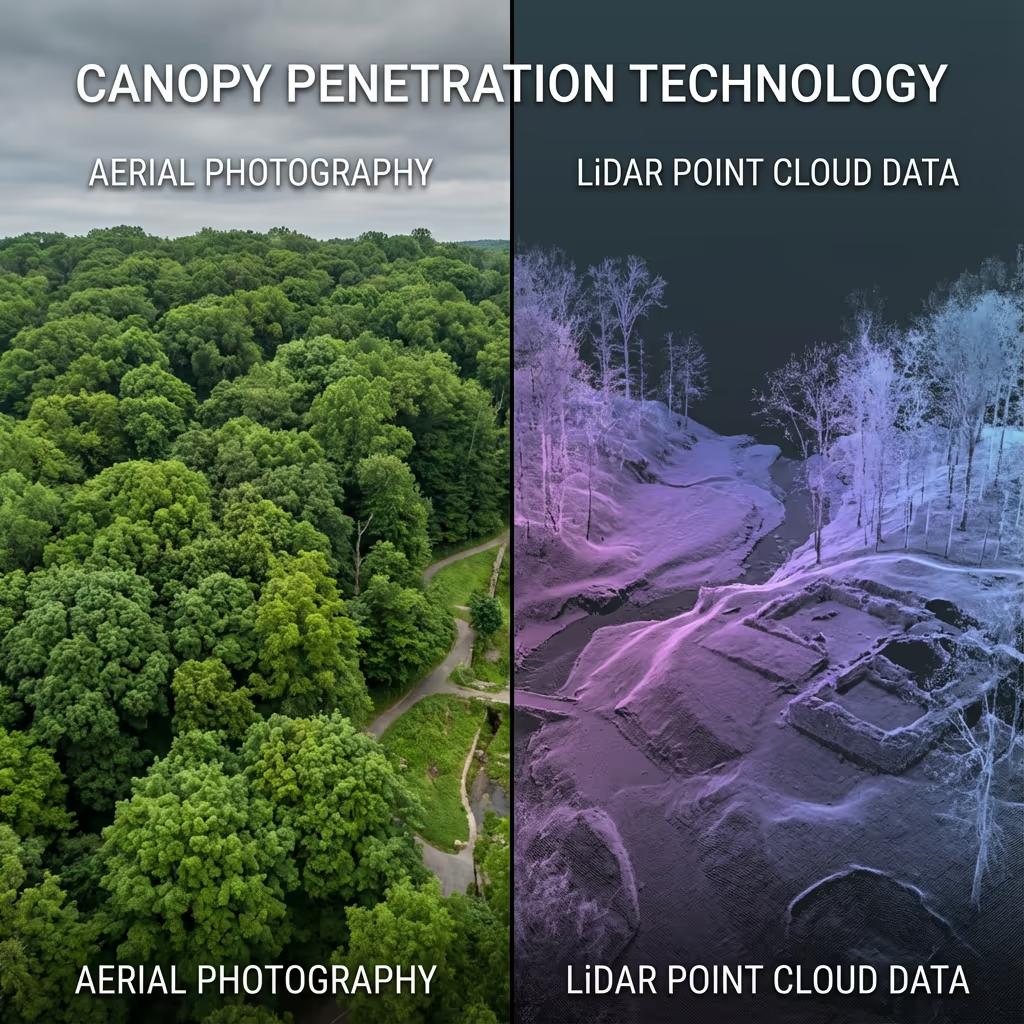

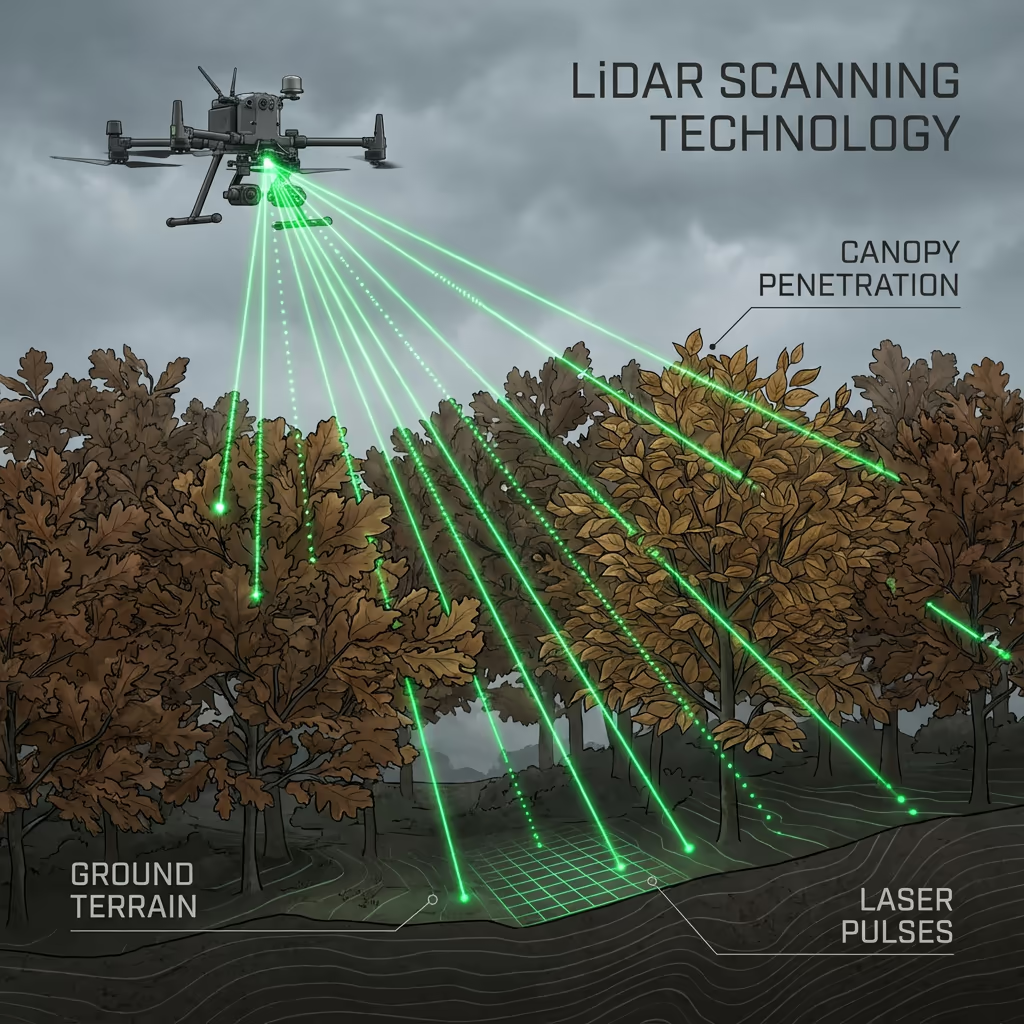

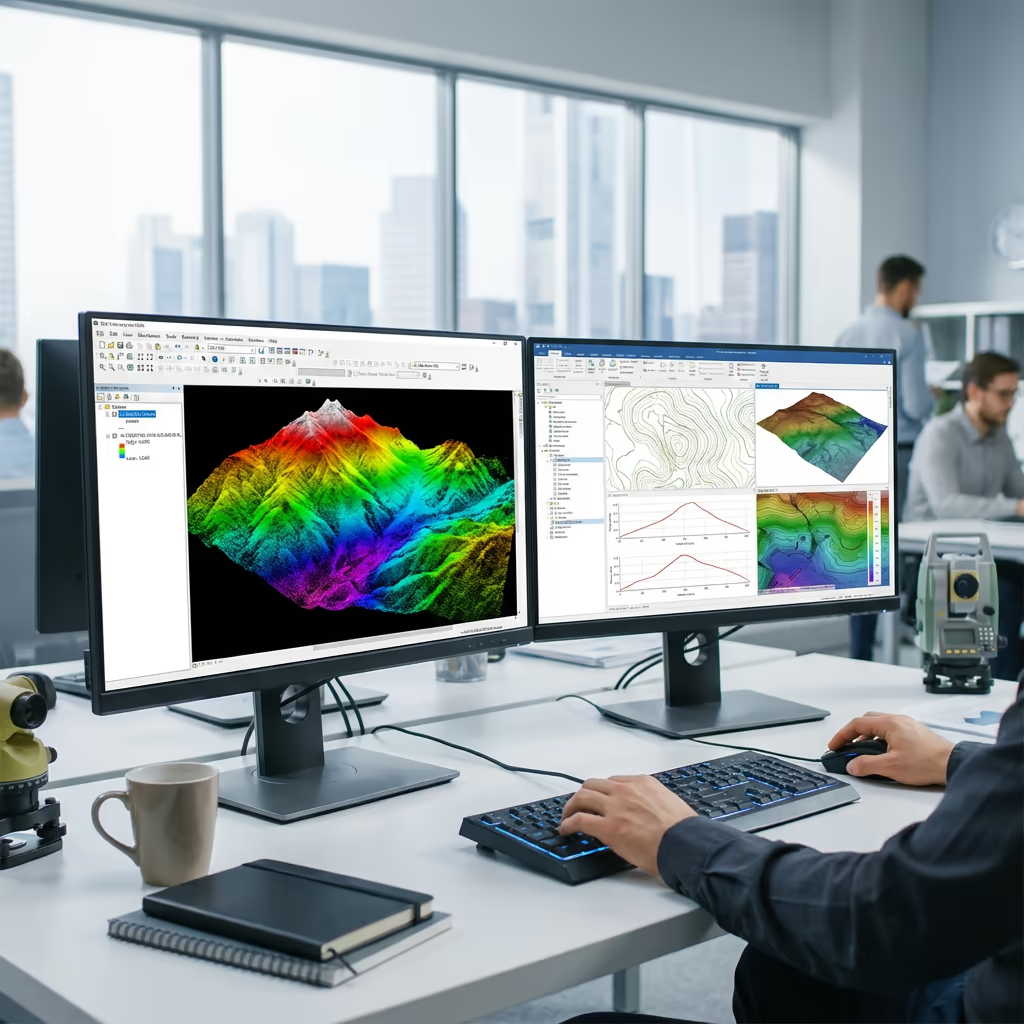

LiDAR Sensors

Penetrate vegetation and capture precise terrain data with laser scanning technology.

Applications

- Forestry & vegetation mapping

- Terrain modelling under canopy

- Flood risk assessment

- Archaeological surveys

- Power line corridor mapping

Thermal Imaging

Detect heat signatures for building diagnostics, energy audits, and industrial inspections.

Applications

- Building thermal surveys

- Solar panel inspections

- Electrical fault detection

- Search and rescue

- Livestock monitoring

RGB & Photogrammetry

High-resolution imagery for detailed 3D models, orthomosaics, and visual inspections.

Applications

- Topographic surveys

- 3D model generation

- Progress monitoring

- Asset inspection

- Marketing photography

Need a specific sensor or payload?

Client Testimonials

Why Clients Rate Our Drone Survey Service 5 Stars

Don't just take our word for it. Here's what industry professionals say about working with us.

“By far the best drone surveying company I've used. Responsive, helpful and report quality is spot on. Extremely diligent in highlighting defects outside of scope. 10+ projects completed and never disappointed.”

Mark Reynolds

Building Surveyor

“DSS's drone roof survey was brilliant. James showed me everything wrong with my roof in about 30 minutes. Quick, professional and easy to understand.”

Helen Parker

Homeowner

“Fantastic company to do business with. Been working with the DSS team since 2021 and it's been an absolute pleasure. Highly recommended.”

Robert Hughes

Property Developer